Direct to Garment Printing vs Direct to Film Printing - What's Best?

Direct to Garment Printing vs Direct to Film Printing - What's Best? Is DTG printing better than DFT printing? There are multiple methods for applying ink to garments, but when it comes to printed t-shirts and other clothing items, two of the most popular choices are direct to garment printing and direct to film printing. We’re going to explore the pros and cons of each technique so you can decide which one will work best with your t-shirt printing business needs.

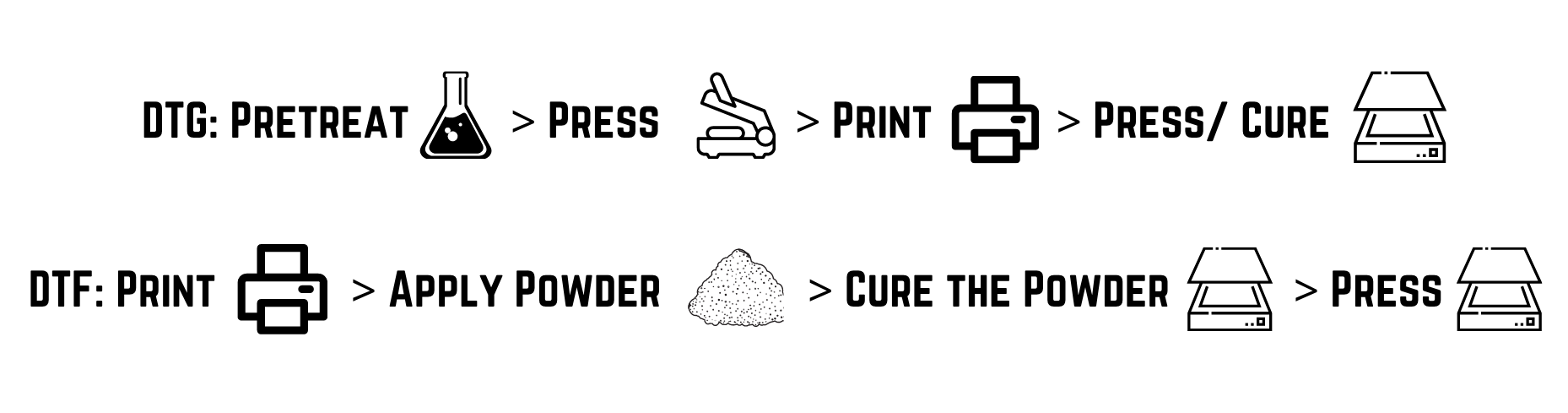

The Major Differences Between DTF and DTG

Quality

Printing both directly on film and directly onto garments gives you a lot of quality options, but each method has its benefits and drawbacks.

There are two main printing methods available: direct-to-garment printing and direct-to-film printing. Direct-to-garment (DTG) is a newer method of screen printing which uses a printer to apply the ink to the shirt and which has been around for quite some time. In fact, DTG has remained virtually unchanged since its inception.

If you are printing on a white garment, DTG is going to be more flexible and easy since it does not require a pretreatment process.

One of its biggest drawbacks, however, is that DTG printing can’t produce high quality color on silk or polyester garments or those with a small number of colors in their design and requires special garment pretreatment beforehand.

This, on the other hand, is one of the advantages of Direct to Film (DTF) printing. It allows you to work with any type of fabric, such as nylon, rayon, polyester, spandex, cotton etc. The higher quality of direct-to-film printing is more ideal for large companies and national brands, who may be interested in larger print runs. However, DTF cannot print images that have effects such as fade away, flames, shadows, or 3D. When it comes to hand feel, DTG is distinctly superior compared to DTF.

Efficiency

In the pretreatment process of DTG, it might discolor some colors of apparels such as reds, oranges, red, and browns. It might happen when directly applying the pretreat on the garment or when heat pressing to cure the pretreat on the shirt. Whereas with DTF, there is no need to use any pretreat at all since the printing is done directly onto a film.

With DTF, the color is printed first with white on top. After, you coat it with an adhesive powder. When it's cured and ready for application, then you can put it directly onto the apparel, heat press it, and the image is transferred to the apparel. It can save you more time and it costs less because there is no need to pay for the pretreat itself or for someone to do the pretreat process.

Watch this video to learn more about the DTF application: Do You Need To Pretreat With Direct To Garment Transfer (DTF) Printing?

Flexibility

T-shirt printing was once pretty difficult and expensive. Screen Printing, the most common type of t-shirt printing, can have high initial fees upon set up and it can be costly when it comes to oversized prints using multiple colors on various locations. However, if you take it to another level, the business opportunity could explode for yourself and your company because now we can put designs on clothes at will without having to stock preprints.

In terms of manufacturing t-shirts, Made-To-Order is what people want these days—even from small mom-and-pop shops. People don't want to pay a high price for something they're never going to wear again because it's out of fashion! With DTF Heat Transfer Printing Technology, designers can make one or two runways per month with ease at a much lower cost. T-shirt printing gets more flexible when combined with DTF. Considering the variety of fabrics you can print on, DTF can be impressive.

Versatility

When versatility matters, DTF is the printer for you.

DTG printing is already known for its versatility and customization, but DTF printing does more! Since there are some materials not entirely suitable for DTG printing such as polyester or polyblends, you can work with DTF printers instead. You can print your transfers in any size or shape and then press them when required. You can also promote your transfers as they are and ship them to your clients without difficulty. DTF transfers can be used on anything from shirts to wallets and everything in between-can your DTG printer print on luggage just as well!

Cost Efficiency

Getting the benefit of DTG without paying too much!

You may know that as printing technology advances, inkjet printing is no longer the gold standard. Dye-sublimation toner (DTG) printers offer better color reproduction and higher resolution images than traditional inkjet printers. But if you've ever checked out a DTG printer, you know they can come with a big price tag and they need expensive ink cartridges.

Thankfully, we now offer DTF printing which is considerably more cost effective than DTG Printing because it does not require pretreatment, it uses a lot less ink.

As comparison:

Watch this video to learn more: Do you need to Pretreat with DTG Transfer (DTF) Printing?

Best of all, we do this at a price comparable to traditional inkjet printing!

The Ultimate Choice

Both DTF and DTG printing are popular methods of direct to garment (DTG) printing, but they each have distinct advantages and disadvantages, ranging from the number of colors you can print to the types of fabrics they can be used on. Before deciding which method will be right for your project, check out the above comparison of DTG vs DTF to make sure you’re choosing the right one.