The Pros And Cons Of Direct To Garment Printing

vs. Screen Printing

start or scale your print-on-demand business

Still looking for the perfect gift this Mother’s Day? We got you covered. Choose from our delicate gift set collection or customize your own.

Screen printing goes way back to the Chinese Song Dynasty (960–1279 AD) as a method for getting prints on fabrics. This method is still prevalent today among amateur and professional printers but technology has allowed other methods to emerge. One of those is the direct-to-garment printing method.

Song Dynasty in China. Photo courtesy of Asia for Educators.

The first mention of direct-to-garment, or DTG, was in an article on Imprint Canada in 1996. It has become very popular in recent years due to its many advantages over other methods of printing T-shirts and other garments. But this form of printing does have its downsides too, and understanding both the pros and cons of DTG will help you make the right decision when it comes time to find a printer that can handle your order. We’ll cover everything you need to know about DTG printing below.

WHAT IS DIRECT-TO-GARMENT PRINTING?

Direct-to-garment printing is a great way for clothing designers, merchandisers, print shops, and sign makers to quickly get custom art onto apparel. But there are also some potential cons of direct-to-garment printing that you should also know about. Meanwhile, screen printing involves the process of pressing down ink through a screen mesh using a squeegee. You may also know it as "silk screening" or "silk screen printing." In this post, I’ll share with you some of the printing pros and cons between these methods so you can decide what’s right for your needs. Let’s get started!

ADVANTAGES OF DTG PRINTING

LESS SETUP TIME, LESS DOWNTIME!

Setting up your day-to-day direct-to-garment printing operations is more quick compared to the traditional screen printing.

Here is how the DTG Printing process goes:

- Prepare the design.

- Pretreat your garment. Make sure it’s dry before it goes into the printer.

- Place the garment on the printer.

- Print away!

- Cure the colors using the heat press.

With the simple steps above, we’d learn that unlike screen printing, DTG printing has no need for minimum order quantities. You can definitely open the door to a print on demand business and now charge a premium for low quantity orders while producing print quality comparable to that of screen printing. You will also not need multiple rooms for things such as wash booths or dark rooms which is a huge plus. DTG is definitely a method that you can start within your home and grow it into a full blown print shop.

Let’s compare it to the screen printing process:

- Create the design onto a transparent acetate film.

- Coat a mesh screen like thiswith emulsion in a dark room.

- Print image on a transparency.

- Expose the setup under a strong light source.

- Take the screen to a wash booth and wash it with water. Now you've got your stencil.

- Add ink on top of the screen mesh.

- Place the shirt on a platen and put the screen mesh on top of it.

- Use a squeegee to push the ink through the screen mesh.

See related video: How To Start Your Printing Business - Ep. 7: Screen Printing

You may also like this video: How To Start Your Printing Business - Ep. 8: DTG | AA Print Supply

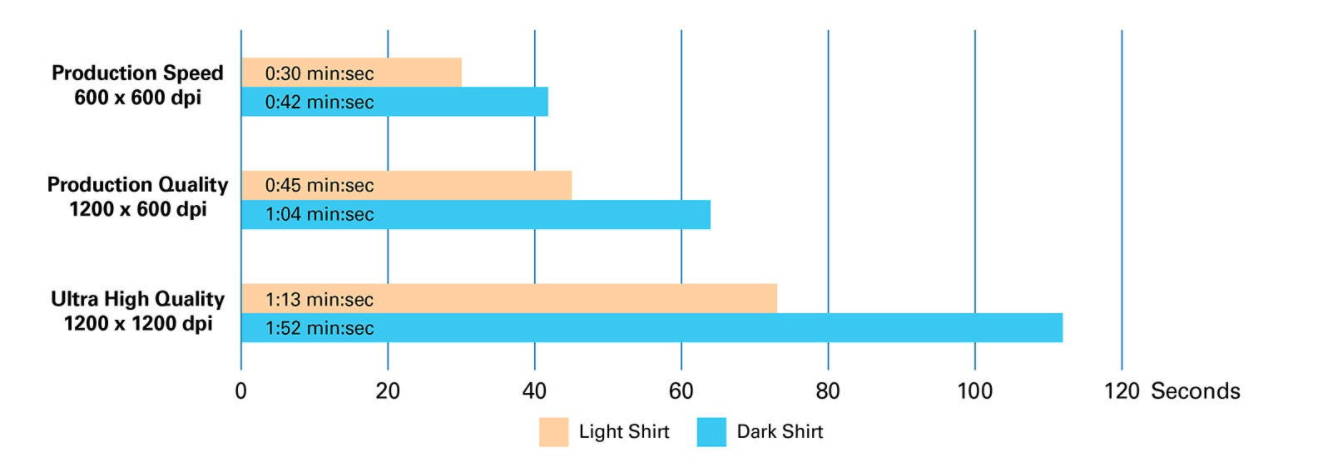

FASTER WITH DTG ON SMALL QUANTITY ORDERS

Below is a comparison of printing speeds when you print with a DTG Printer such as the Epson SureColor F3070. Keep in mind that the mode settings you choose will largely determine how quickly a print can be completed.

Epson F3070 Print Speed vs. Productivity (on a 7”x11” image)

ENDLESS COLOR AND DESIGN OPTIONS

With screen printing, you can have very limited choices when it comes to colors. When you print, you have to lay out each color one at a time and do layers as needed. The more colors and details you’ve got in your design, the more work you're going to deal with when you print it on a garment! On the other hand, direct-to-garment printing will allow you to print complex designs with multiple colors simultaneously with just one pass onto light-colored garments or just two passes for dark garments. You are assured to get high quality prints and hand-feel that your customers will surely love. Let your creativity flow without worries.

DTG has great print quality, unmatched by many other print methods and can get fine details better than screen printing. It also provides the versatility of printing one off designs without much preparation. Garments can also be pretreated up to six months ahead of time to minimize preparation times. This is achieved with DTG Printing ink technology such as the DuPont Artistri ink that produces vibrant prints on a variety of textile or the Epson UltraChrome DG ink that produces clean, bright images with superior washability on dark and light garments.

GREAT FOR SHORT TO MEDIUM PRODUCTION

With screen printing, you can have very limited choices when it comes to colors. When you print, you have to lay out each color one at a time and do layers as needed. The more colors and details you’ve got in your design, the more work you're going to deal with when you print it on a garment! On the other hand, direct-to-garment printing will allow you to print complex designs with multiple colors simultaneously with just one pass onto light-colored garments or just two passes for dark garments. You are assured to get high quality prints and hand-feel that your customers will surely love. Let your creativity flow without worries.

DTG has great print quality, unmatched by many other print methods and can get fine details better than screen printing. It also provides the versatility of printing one off designs without much preparation. Garments can also be pretreated up to six months ahead of time to minimize preparation times. This is achieved with DTG Printing ink technology such as the DuPont Artistri ink that produces vibrant prints on a variety of textile or the Epson UltraChrome DG ink that produces clean, bright images with superior washability on dark and light garments.

DISADVANTAGES OF DTG PRINTING

Direct-to-garment (DTG) printing allows for more complex designs than screen printing, but with that added complexity comes a few disadvantages. Here, you may find that screen printing is more suitable for your business needs.

CHALLENGE WITH CERTAIN MATERIALS

There are only certain places DTG printers can print on shirts—no collars or cuffs, typically—which limits your design options. Additionally, there’s no way to match DTG printing between two pieces of clothing, which is something you can do with screen printing.

It can be difficult to print on polyester, even more so when you do it with DTG Printing. Since polyester is made of plastic it doesn't bond well with water-based DTG inks. With DTG printing, it's best to use 100% cotton fabrics. You might have more success with screen printing on polyester but it will still require choosing the right polyester blend, trying different inks, and controlling the temperature to produce great quality designs.

Tip: Begin with an initial layer of low-bleed ink/no-bleed ink to avoid the common problem of dye migration.

INITIAL INVESTMENT IS HIGH

The initial investment for a DTG Printer is high. The Epson SureColor F2100 Direct to Garment Printer retails at $ 14,995 while the Epson SureColor F3070 Industrial Direct to Garment Printer is at $49,995.

Below is a list of the other equipment you'll need that you can find at our store and its price range.

1. Pre-Treatment Machine - From $1,495 to $7,750

2. Heat Press - From $2,050 to $7,875

3. Raster Image Processing (RIP) software for DTG printer (Optional) - From $1,200 to $2,400

Important to note that DTG printing only works up to 16” x 20” heat presses.

With screen printing, a manual printing press starts just at $335 (Vastex V-10 CraftPrinter Screen Printing Press). Other equipment are:

1. Flash Dryer - From $525 to $4,495

2. Exposure Unit - From $857 to $8,367

Even though the initial investment is high, you have many options to finance your equipment, and even with slower per print speeds compared to screen printing DTG still has a smaller preparation time and can charge more per print due to its no minimum order quantity and high quality prints.

LEARNING CURVE WITH THE PRETREAT STEP

DTG printing requires adding a pretreat layer so the ink can bond to the shirt and it is also the primer coat for CMYK. Knowing how much pretreatment to use on various textiles and understanding how to use and maintain the pretreatment machine can be a challenging learning curve for some. It requires time to master the skill to use it but once you do, you'll experience its great outcome!