Exploring the Science

Learning more to help your business

"The science of today is the technology of tomorrow."

- Edward Teller

After perusing the interwebs for a minute, I found a ton of information on how to DO the DTF process, or a step-by-step guide. What I have not found is a comprehensive collection or article on HOW the process works. So, I’m not one of those science types; I’m a Star Wars nerd wrapped in a dad bod. With that being said, I’ll try not to make this a boring explanation. We’ll go through OUR step-by-step guide and I’ll break down how it works. Ready? Let’s go.

A couple of quick terms so that we don’t get too lost along the way:

“TPU”or “Thermoplastic Polyurethane”: a category of plastic created when a polyaddition reaction occurs between diisocyanate and one or more diols (BORING). We use TPU as a proper noun in most cases to describe the powder. Just keep in mind that the DTF powder is essentially a finely ground plastic with a “low” melting point (if 300 degrees Fahrenheit is low).

“PET” or “Polyethylene terephthalate”: the most common thermoplastic polymer resin of the polyester family and is used in fibers for clothing and containers for liquids and food. The DTF film is a specially coated PET product. Awesomely heat resistant and easily coated.

There are three or more layers of coating on any piece of PET film. How they are manufactured and attached to the film are trade secrets. But what I can tell you is the layers are (from the PET and up):

- PET sheet

- Release Layer (mostly “oil” based)

- Anti-Static Layer

- Ink Absorption layer

Step 1: You must print your CMYK down first, then your white layer afterwards (which is the opposite of direct-to-garment (DTG): You are printing onto the PET film directly into that ink absorption layer. This is the base that will be the foundation for the White ink and the TPU powder. NOTE: THE COATINGS ARE NOT ON BOTH SIDES OF THE FILM. We’ll mention the other layers as they get relevant later. Keep in mind that the Anti-Static layer is working through every step to keep the PET film from clinging to everything.

Step 2: Apply the powder uniformly while the print is still wet to ensure it sticks. Carefully shake off the excess powder so there’s no remaining other than the print. This is extremely important as this is the glue that holds the print to the fabric: This is where the TPU comes into play. The DTF Powder is a specific type of powdered TPU with a low heat tolerance. This allows the “plastic” to melt easily, acting as an adhesive to attach the ink/powder combo to the fabric and adhere it through curing and pressing.

Step 3: Cure your newly powdered print: We already mentioned the TPU melting to form a glue-ish adhesion. The PET film has a higher melting point than the TPU, so the PET film won’t get heat damaged and the TPU will melt uniformly onto the ink.

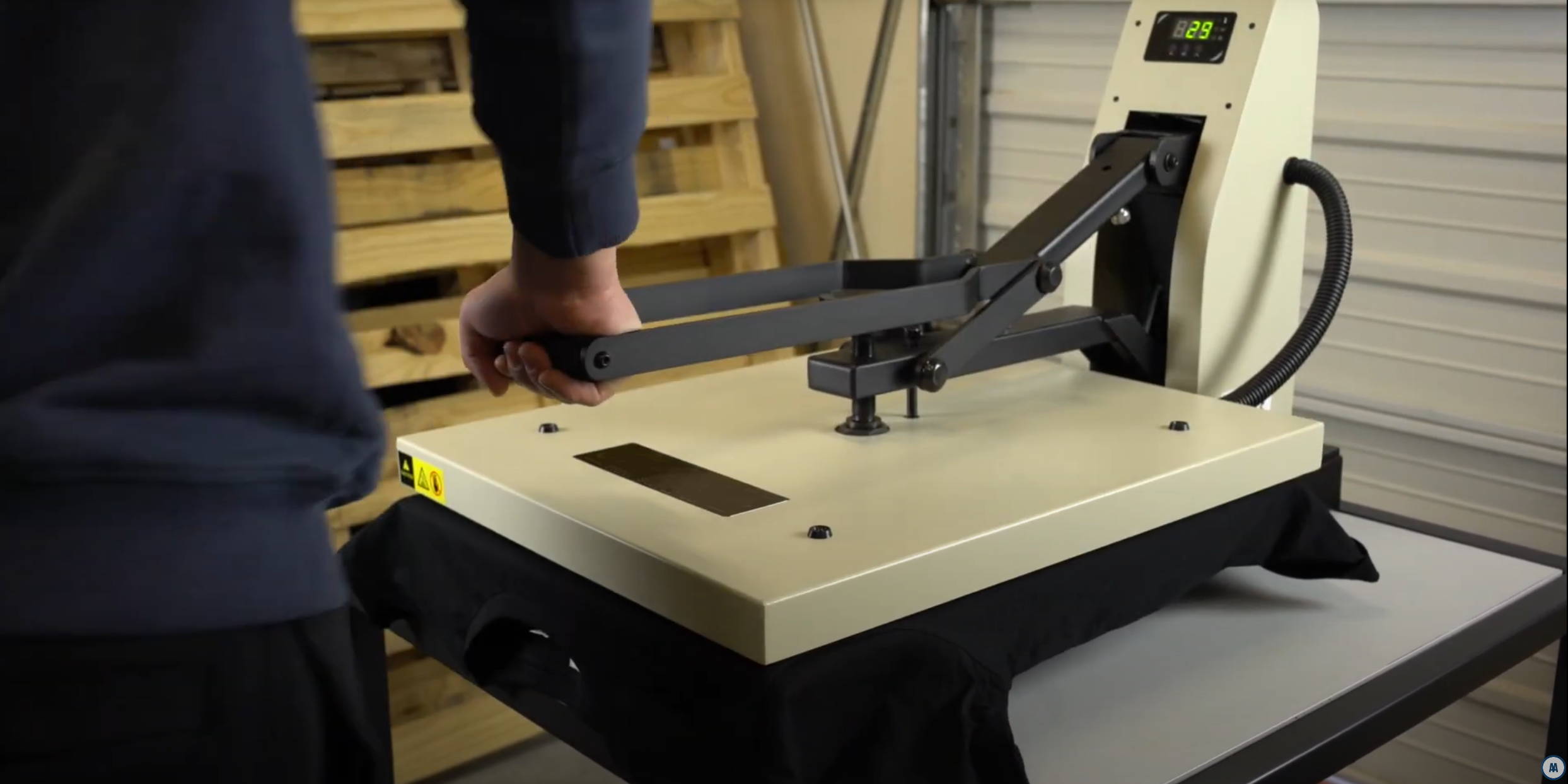

Step 4: Now that the transfer print is cooked, you are ready to apply it onto the garment. Use your heat press to transfer the printed film: The transfer step is simple to explain. You are heating up that “Release Layer” and the TPU to adhere to the garment.

Step 5: Peel the carrier sheet off the garment or fabric: And the “Release Layer” is finally utilized to have a clean peel that doesn’t peel off the graphic or TPU.

And that’s it. A little more of a technical breakdown of the process, but not too bad. Hopefully we've both learned something more about the science behind the stuff that helps our businesses thrive. If you have any questions about this process, feel free to hit us up through our “Contact Us” page, and one of our specialists will be more than happy to assist.

Meet our author

Steven De Hoff

Content Writer & Editor

Steven has 10+ years of experience in the E-commerce space with an emphasis in storefronts and product listings. A classical connoisseur of the internet, Steven spends his free time staying away from it. Instead choosing to be a dad and disc golfer.

You can meet Steven and more of the friendly All American Print Supply Co team by visiting the company live events calendar and our YouTube channel.